Aspen Plus Multiple Input Ina Reactor

Open a new case by choosing a blank simulation. Aspen Polymers - Modeling of polymerization reactors and polymer thermodynamics.

Aspen Plus Tutorial Rstoic Requil Reactors By Scuolatech Youtube

It does have the ability to design mulit-tube reactors with and without internal cooling and heating.

Aspen plus multiple input ina reactor. In aspen terminology the process variable or controlled variable is denoted by PV the set point is represented by SP. You can input values for pressure temperature heat duty. Solving Linear Equations with Gaussian Elimination 3.

The residence time for a PFR is the same as for a batch reactor. Added to the Aspen Plus Aspen Plus version 111 software using a special installation script it can be applied as a unit operation block in user-definable. The following results were found and reproduced from a PFD file in.

The feed gas and sweep gas flow in a countercurrent fashion on both sides along the membrane. RBatch uses holding tanks to interface the unsteady state batch operation with the steady state flowsheet environment in Aspen Plus Fig. Reaction Analysis and Reactor Design using Aspen Plus Enables the attendee to recognize the various reactorreaction capabilities within Aspen Plus.

StartProgramsChemEAspen Plus User Interface 2. 22 The model implementation structure The WGSMR-model is a user model written in Fortran. Solving Set of Linear Equations 2.

The best source of documentation for most Aspen unit operations is to use the online help by selecting the F1 key while in a. Aspen Plus users who want to improve their skills at analyzing reactions and designing reactors. It can be found in the start menu under.

Install RPlug Kinetic reactor. Demonstrates the use of reactor models through an example problem on the production of ethyl acetate in Aspen Plus. Up to 10 cash back Aspen Plus serves as the engineering platform for modeling processes from Upstream through Gas Processing to Petroleum Refining Petrochemicals Chemicals and Pharmaceutical processes.

Exam Scope for Aspen Plus with EDR. Aspen requires input of reactor dimensions in lieu of reactor volume. To start the simulation initial values of 01 meter in diameter and 1000 meter in length are assumed.

The flow diagram was drawn with a single feed connected to a GIBBS reactor and a single product. This person also demonstrates fluency with some more advanced topics such as convergence troubleshooting and detailed distillation modeling. Start the Aspen program.

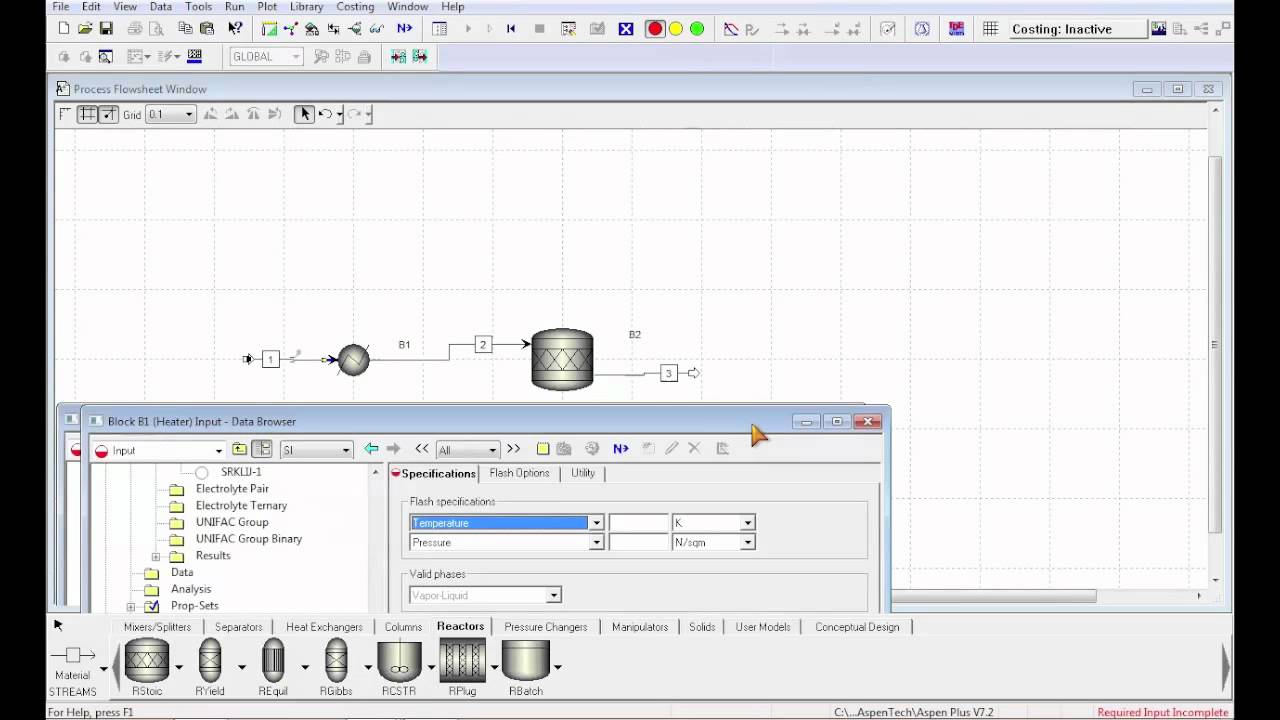

Click on the RPlug icon then release left mouse button. The reactor flow sheet includes two LC1 and TC single-inputsingle output SISO control loops. To input the reactor specifications double click on the reactor block.

Here are the results of simulating the Water Gas Shift reactor in Aspen. Fluidized bed reactor is useful for heterogeneous multiphase reactions separations size enlargement coating and blending in chemical and pharmaceuticals industries. Choose Data from the main menu and click Setup.

Move cursor to pfd screen and then press left mouse button only once. Made by faculty at Lafayette College and. Choose input having a composition of pure ethylbenzene at 217gmols 880 K 1378 bar.

I would assume that Aspen will have similar capabilities. This online course is designed around a series of chemical reactor examples which we work through to a model solution. The first problem posed in Smith et al Example 155.

Later on in the quarter you will want to open up an existing simulation but now we will use the template option. The batch reactor unit process RBatch was used in Aspen Plus to simulate unsteady state batch process. Exam scope for Aspen Plus with Distillation Modeling Properties Environment.

We will examine multiple reactions in a two-reactor plug flow reactor train using Aspen Plus. The reactor Data Browser opens. We will use SI units for all reactors with kinetics.

This person will also demonstrate skills in advanced topics such as convergence troubleshooting and heat exchanger design using the EDR interface. Video Lecture 105 of 50. This package is available within Aspen Plus or Aspen Properties rather than via an external menu.

To achieve 90 reaction conversion in a plug flow reactor. Aspen Plus 2006 In this session you will learn how to create a stoichiometric reactor model in Aspen Plus 2006. An Aspen Plus Certified demonstrates skills required to build models and interpret results using Aspen Plus with Aspen Exchanger Design and Rating EDR.

Reactor Typesby University of Colorado. Reactor Modeling in Aspen Plus There are seven blocks for reaction modeling in Aspen that can perform calculations based on the stoichiometry yield equilibrium and Gibbs minimization plus the kinetics models for CSTR and PFR. This reactor has an advantage over traditional packed bed reactor because it has a better heat and mass transfer.

To develop a model and simulation of this reactor with advanced. Aspen Plus models batch reactors in steady state so a real -world plant running batch reactors would need several reactors in parallel with staggered start and end times to. Using the Model Library click on Reactors and then choose RPlug.

Compare this to the residence time required for a CSTR RX-003_CSTR_CIStoTRANS. Therefore this control structure is a multi-inputmulti-output MIMO or simply multivariable closed loop system. It is found that the conversion of C4H10 reaches a maximum of about 72.

Aspen RPLUG reactor model is used with reactor type Adiabatic Reactor and reaction model ISOMER. Aspen Plus Fluidized Bed Reactor Simulation The fluidized bed reactor is a reactor in which the fluid from the bottom of the reactor keeps the solid catalysts suspended inside the reactor. Specify the feed composition as a mole fraction.

Close the Streams tab. Only one case will be shown. Both the analytical solution and design spec in Aspen Plus produced the same required residence time of 1001 min.

All of the phase equilibria and mixture property methods discussed on this site are accessible in either Aspen Plus or Aspen Properties. Water Gas Shift Reactor. The window that appears can be seen in Figure 1.

Bisection Live Method 7. Do not use the templates for consistent units when specifying your kinetics. BatchSep - Batch distillations.

Provides hands-on experience modeling various reactors and analyzing reaction results. Choose what type of simulation you would like to use. An Aspen Plus Certified User demonstrates the practical skills to build models and interpret results using Aspen Plus.

Komentar

Posting Komentar